CLP中華電力 x TÜV萊茵,攜手共建燃氣輪機聯合循環發電項目 | CLP and TÜV Rheinland join hands to build a combined cycle gas turbine (CCGT) power generation project

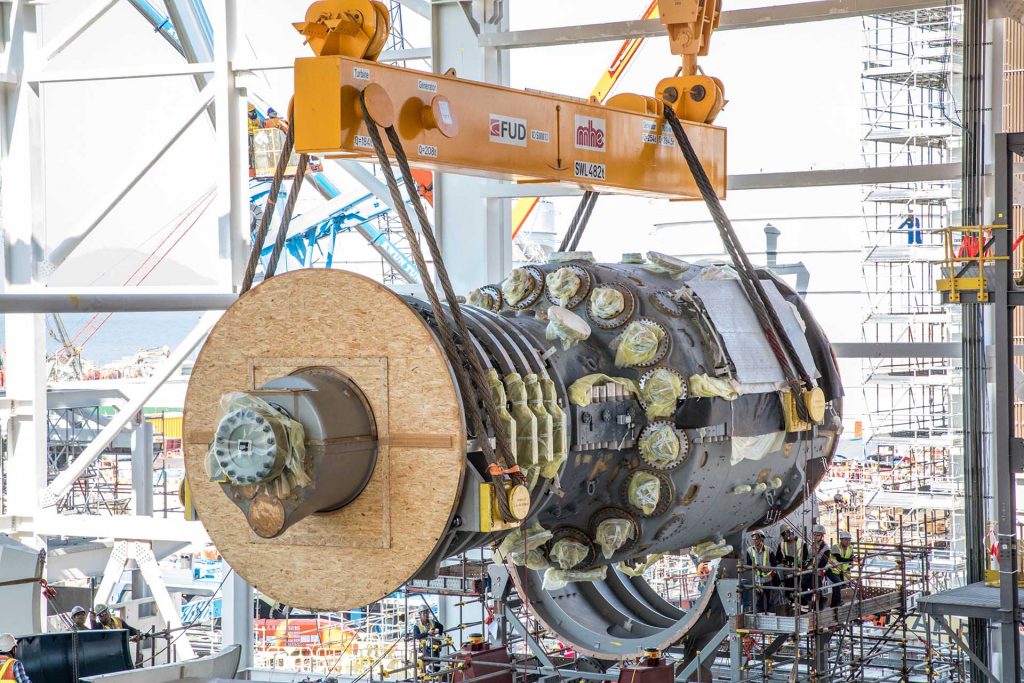

- CCGT D1項目的最大挑戰首先是技術領先,設備採用西門子全球最先進的SGT5-8000H級燃機,也大中華區首個H級燃氣電廠,SST5-5000蒸汽輪機,SGen5-3000W發電機和另加HRSG餘熱鍋爐系統,總裝機容量將達到550MW。

- 另一大挑戰,作為項目設計、設備提供商以及調試方的西門子,其供應鏈體系遍布全球近20個國家,需要全球領先的第三方檢驗機構協助CLP更好地履行業主在製造階段的質量、催交以及現場安裝的監督職責。

- 此外,整個項目參與方,除了西門子,還有ARUP等各專業領域的領先企業,由於項目管理協調比較複雜,各地要求各不相同,最後按照香港法規要求,以及HRSG餘熱鍋爐等承壓部件法規,綜合考慮,CLP最終選擇TÜV萊茵作為合作夥伴,為其提供業主方的檢驗、管理和諮詢服務。

- Firstly, the biggest challenge of CCGT D1 project lies in its cutting-edge technology. It uses the world’s most advanced SGT5-8000H gas turbine produced by Siemens (making the Black Point Power Station the first H-class gas-fired power station in Greater China), SST5-5000 steam turbine, SGen5-3000W generator and heat recovery steam generator (HRSG) system, with a gross installed capacity of 550MW.

- Another challenge lies in the fact that Siemens, the project engineering designer, equipment supplier and commissioning party, has a supply chain system covering nearly 20 countries, and therefore a world-leading third-party inspection body is required to assist CLP in better performing its duties in ensuring quality during manufacturing, expediting delivery and supervising field installation.

- Additionally, apart from Siemens, some other industry leaders such as ARUP are also involved in the project. Given that project management and coordination is very complex and that different places have their respective requirements, CLP, after overall consideration, has chosen TÜV Rheinland as its partner to provide inspection, management and consultation for it as the owner according to the regulations of Hong Kong and specifications for pressure parts such as HRSG.

- On behalf of CLP, TÜV Rheinland conducted quality management system audit on ARUP and other contractors at the early, middle and late stage of the project respectively. All the parties have been impressed by the professional insight of TÜV Rheinland’s auditing experts, and convinced by their solid conclusions and sound advices, which effectively promotes CLP’s management of onsite contractors, ensures continuous improvement and reduces the project’s risks.

- TÜV Rheinland has under its belt rich expertise and experience, with an acute insight into Hong Kong’s regulations. As the RIB of Hong Kong Labour Department, TÜV Rheinland inspected the installation of HRSG in strict accordance with Hong Kong’s regulations and based on the installation schedule. During the stages of field installation, commissioning, firing and trial operation, TÜV Rheinland also demonstrated a professional and rigorous work attitude, particularly when it came to welding, electric meter, anti-corrosion coating and performance verification.

- With its global project management experience and a professional team of engineers, TÜV Rheinland has won the recognition of the customer. During the factory acceptance test (FAT) for Siemens gas turbine, the customer remarked that “the German engineers not only boast solid technical know-how, but are also fully prepared for the test. During the entire test, the engineers listen attentively to the customer’s requirements, try hard to figure out ways to satisfy the customer’s needs and strive to safeguard the customer’s rights.”

- TÜV Rheinland’s global network provides convenient services for the project. The project’s suppliers involve hundreds of factories from nearly 20 countries including Germany, US, South Korea and China. Promptly responding to customer’s requirements and integrating global resources, TÜV Rheinland provides whole-process and full-cycle professional services from review of inspection and test plan (ITP) and other documents, verification of raw materials, supervision of process quality & schedule to factory acceptance, as well as from equipment gate-in, installation, commissioning, initial firing to thermal joint commissioning. TÜV Rheinland also manages the equipment hierarchically and dynamically according to the risk matrix.

- During the quality inspection of D1 project, TÜV Rheinland identified and tackled complex problems in manufacturing and supply chain, and ensured that all equipment’s conformance to technical specifications and quality standards by eliminating non-conformance in the factories. Not a single quality accident occurred during the project, which proves that appropriate project measures and feasible inspection plans have been put in place to achieve the project’s quality goal.

- Combined cycle gas turbine (CCGT) D1 successfully conducted initial firing and synchronization on Jan. 24, 2020 and Jan. 29, 2020 respectively, which marks an important milestone of the project. After intensive efforts in thermal joint commissioning for several months, CCGT D1 finally began to generate power on Jun. 20, 2020.

大型工業項目的設備不管是由設施運營商直接購買,還是通過工程承包商購買,它們都必須達到項目規定的質量和安全性能,並且按時交付至現場,同時還必須符合目的地法規及國際相關標準要求。因此,在此類設備的採購過程中,必須將項目風險和運營風險降至最低。這正是TÜV萊茵工業服務-全程供應鏈服務努力為客戶實現的價值所在。

從2017年至今,TÜV萊茵持續助力CLP中華電力發電設備採購項目,制定和實施供應商檢驗計劃,確保項目順利開展,有效避免運營風險並達到規定的質量和安全性能。

關於CLP中華電力

作為全球規模最大的燃氣聯合循環發電廠之一,CLP中華電力於1901年在香港成立,當時電力仍然是新興事物。今天CLP集團以香港為家,並把業務擴展至亞太地區,集團投資中國內地、印度、東南亞、台灣及澳洲的能源市場,營運多元化的發電組合,燃料包括煤炭、天然氣、核能、風力、水力及太陽能。業務範圍包括發電、輸電和配電服務以及電力及燃氣之零售業務。

客戶挑戰

在龍鼓灘發電廠,CLP中華電力(簡稱“中電”)原有8台CCGT裝機容量共2500MW, 於1996至2006年投產,由中電負責運營,也成為了首家在香港引入天然氣發電的電力公司,通過燃氣發電,使得電力需求大幅增加的同時,成功降低總排放量。為配合政府訂立2020 年將本地發電燃料中天然氣的比例增至大約50%的燃料組合目標,以減少碳排放,因此,在龍鼓灘發電廠內,新增一台聯合循環燃氣渦輪發電機組,即為此次TÜV萊茵協助中電開展的CCGT D1項目。

TÜV萊茵解決方案

1.TÜV萊茵代表CLP對ARUP等承攬商分別在項目初、中、末期三階段進行質量管理體系審核。 TÜV萊茵審核專家的專業洞察、紮實的審核結論以及中肯的建議贏得各方一致信服,有效促進CLP對現場承包商的管理,確保持續改進,降低項目風險。

2.TÜV萊茵擁有豐富的行業知識和經驗,洞悉香港等法規。作為香港勞工署RIB,配合安裝進度,嚴格按照香港法規要求對HRSG安裝監檢。並在現場安裝、調試、點火,試運行階段,焊接、電儀、防腐塗裝以及性能驗證等環節,展現了專業嚴謹的工作態度。

3.TÜV萊茵憑藉全球化的項目管理經驗以及專業的工程師團隊,獲得了客戶的認可。西門子燃氣輪機FAT在最終驗收時,提及德國工程師“不僅有紮實的技術知識,而且對測試有充分的準備。在整個測試工作中,傾聽客戶的心聲,思考客戶的需求,爭取客戶的權利。

4.TÜV萊茵的全球網絡,為項目提供便捷服務。整個項目供應商遍及德國、美國、韓國以及中國等近20個國家,上百家工廠。 TÜV萊茵迅速響應客戶需求,整合全球資源,從ITP等文件審核、原材料驗證、過程質量和進度監督到出廠驗收,從設備進場、安裝、調試到首次點火、熱聯調,提供全過程、全週期的專業服務。並根據風險矩陣,對設備分級動態管理。

成果和收益

1.在D1項目的質量檢驗中,很好地發現並處理複雜的製造及供應鏈問題,將Non-Conformance解決在工廠,確保所有設備符合技術規範和質量標準。項目過程中也未出現質量事故,證明了整個項目措施得當,檢驗計劃可行,實現了項目的質量目標。

2.目前聯合循環燃氣(CCGT) D1於2020年1月24日成功首次點火,並於2019年1月29日實現同步,圓滿實現該項目的重要里程碑。經過幾個月緊張的熱聯調,最終於2020年6月20日正式運行發電。

關於TÜV萊茵

我們提供完整的工程項目技術諮詢,項目協調和項目管理服務,對整個項目在採購、製造、安裝和調試環節中每一步的質量保證提供專業及合理化的技術支持和解決方案。

我們提供完整的工程項目技術諮詢,項目協調和項目管理服務,對整個無論您處於哪個領域,德國萊茵TÜV在供應商選擇、生產、運輸和安裝各個階段提供的服務都能為您在整個供應鏈中增值。同時,我們幫助您選擇有資質、有能力的供應商,保障材料與部件的質量,從而避免交貨延誤。項目在採購、製造、安裝和調試環節中每一步的質量保證提供專業及合理化的技術支持和解決方案。

CLP and TÜV Rheinland join hands to build a combined cycle gas turbine (CCGT) power generation project

Whether purchased by facility operators or engineering contractors, the equipment of a large-scale industrial project must meet its requirements on quality and safety performance, and be delivered to the site on time. Meanwhile, the equipment must conform to local regulations and related international standards. Therefore, efforts must be made to minimize the risks of the project and its operation during the purchase of such equipment. This is exactly the value that TÜV Rheinland Industrial Service-Whole Supply Chain Service strives to realize for customers.

Since 2017, TÜV Rheinland has been constantly cooperating with CLP on the power generation equipment purchasing project. By making and implementing supplier inspection and test plan (ITP), it has ensured the smooth progress of the project, and helped the project to effectively avoid operation risks and achieve the required quality and safety performance.

About CLP

CLP, one of the world’s largest combined cycle gas turbine power stations, was founded in Hong Kong in 1901 when electricity was still a novelty worldwide. Based in Hong Kong, CLP Group has now expanded its business to the entire Asia-Pacific region. With investments in the energy sector of the Chinese mainland, India, Southeast Asia, Taiwan and Australia, it boasts a well-diversified power generation portfolio including coal, natural gas, nuclear energy, wind power, hydraulic power and solar energy. CLP Group is engaged in power generation, transmission and distribution, as well as electricity and gas retail.

Challenges of the Project

Operated by CLP and put into operation by stages from 1996 to 2006, the Black Point Power Station, with 8 combined cycle gas turbines (CCGT) with a gross installed capacity of 2,500MW, pioneered the use of natural gas for power generation in Hong Kong. By using natural gas, it has succeeded in reducing total emissions while at the same time meeting the increasingly higher demand for electricity. In line with the government’s goal of increasing the proportion of natural gas in local power generation fuels to about 50% in 2020 in order to reduce carbon emissions, CLP has installed a new CCGT generator set at the Black Point Power Station, and TÜV Rheinland has been chosen to assist with the CCGT D1 project.

TÜV Rheinland’s Solutions

Results and Benefits

About TÜV Rheinland

我們提供完整的工程項目技術諮詢,項目協調和項目管理服務,對整個項目在採購、製造、安裝和調試環節中每一步的質量保證提供專業及合理化的技術支持和解決方案。

We offer a complete package of services in technology consulting, project coordination and project management for engineering projects, and provide professional and sound technical support and solutions for quality guarantee along a whole project from purchasing, manufacturing, installation to commissioning.

我們提供完整的工程項目技術諮詢,項目協調和項目管理服務,對整個無論您處於哪個領域,德國萊茵TÜV在供應商選擇、生產、運輸和安裝各個階段提供的服務都能為您在整個供應鏈中增值。同時,我們幫助您選擇有資質、有能力的供應商,保障材料與部件的質量,從而避免交貨延誤。項目在採購、製造、安裝和調試環節中每一步的質量保證提供專業及合理化的技術支持和解決方案。No matter in which segment you operate—TÜV Rheinland’s services during Vendor Selection, Production, Shipment and Installation, can add value along the entire supply chain, we also help you select qualified and capable suppliers, to assure the quality of materials and components and to avoid delays in delivery.

熱門分享